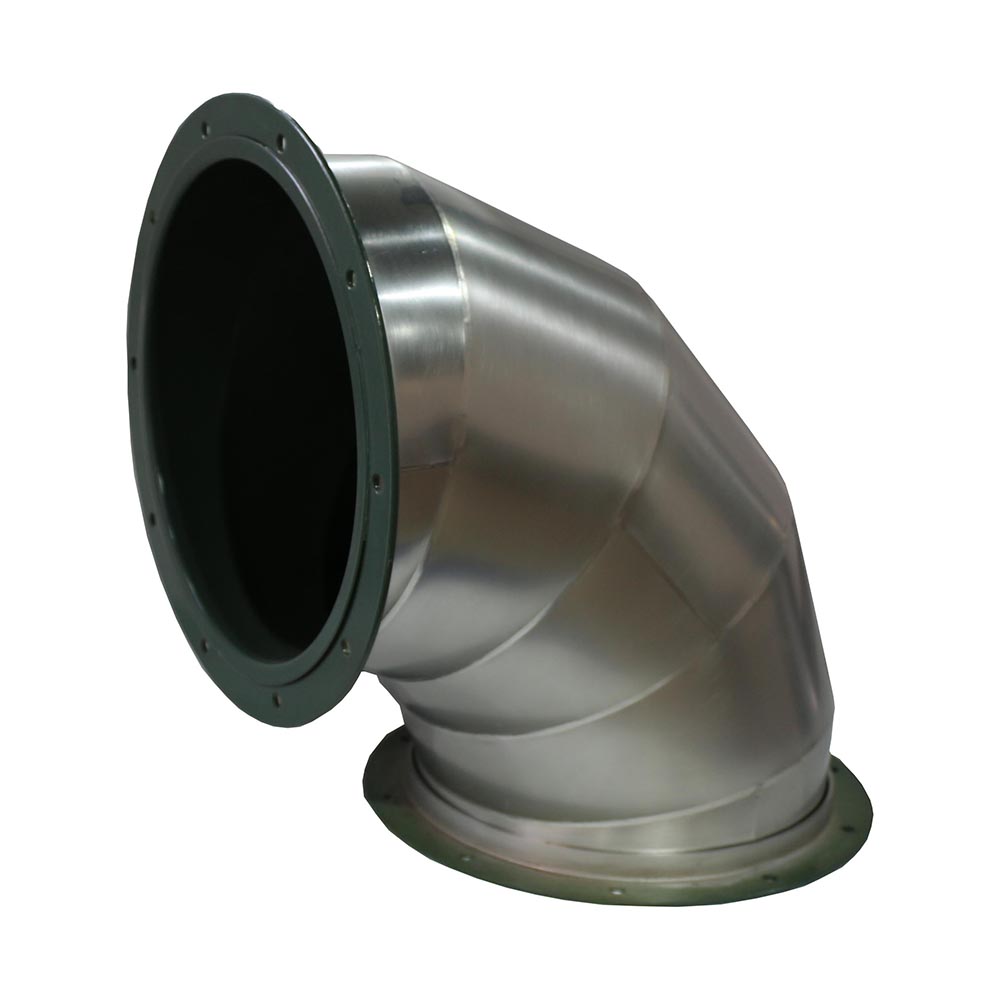

SUS304/ Teflon Coating 90° eelbow (5 Gore)

| Inombolo yenqaku. | Ububanzi (mm) | Isidanga | Irediyasi (mm) | intsimbi (PC.) | Ukutyeba (mm) |

| E90-0250 | 250 |

|

|

| 0.8 (okanye isicelo somthengi) |

| E90-0300 | 300 |

|

|

| 0.8 (okanye isicelo somthengi) |

| E90-0350 | 350 |

|

|

| 0.8 (okanye isicelo somthengi) |

| E90-0400 | 400 |

|

|

| 1.0 (okanye isicelo somthengi) |

| E90-0450 | 450 |

|

|

| 1.0 (okanye isicelo somthengi) |

| E90-0500 | 500 |

|

|

| 1.0 (okanye isicelo somthengi) |

| E90-0550 | 550 |

|

|

| 1.0 (okanye isicelo somthengi) |

| E90-0600 | 600 |

|

|

| 1.0 (okanye isicelo somthengi) |

| E90-0650 | 650 |

|

|

| 1.0 (okanye isicelo somthengi) |

| E90-0700 | 700 |

|

|

| 1.2 (okanye isicelo somthengi) |

| E90-0750 | 750 |

|

|

| 1.2 (okanye isicelo somthengi) |

| E90-0800 | 800 |

| R=01 |

| 1.2 (okanye isicelo somthengi) |

| E90-0850 | 850 |

|

| 1.2 (okanye isicelo somthengi) | |

| E90-0900 | 900 |

| R=1.5x01 |

| 1.2 (okanye isicelo somthengi) |

| E90-0950 | 950 |

|

| 1.2 (okanye isicelo somthengi) | |

| E90-1000 | 1000 |

|

|

| 1.5 (okanye isicelo somthengi) |

| E90-1100 | 1100 |

|

|

| 1.5 (okanye isicelo somthengi) |

| E90-1200 | 1200 |

|

|

| 1.5 (okanye isicelo somthengi) |

| E90-1300 | 1300 |

|

|

| 1.5 (okanye isicelo somthengi) |

| E90-1400 | 1400 |

|

|

| 1.5 (okanye isicelo somthengi) |

| E90-1500 | 1500 |

|

|

| 1.5 (okanye isicelo somthengi) |

| E90-1600 | 1600 |

|

|

| 1.5 (okanye abathengi bacele) |

| E90-1700 | 1700 |

|

|

| 2.0 (okanye isicelo somthengi) |

| E90-1800 | 1800 |

|

|

| 2.0 (okanye isicelo somthengi) |

| E90-1900 | 1900 |

|

|

| 2.0 (okanye isicelo somthengi) |

| E90-2000 | 2000 |

|

|

| 2.0 (okanye isicelo somthengi) |

Phawula:

1. Umbhobho wedayamitha ongaphezulu kwe-2000mm uyafumaneka xa uceliwe.

2. Ubukhulu bombhobho wakhiwe kwi-SMACNA "imigangatho yokwakhiwa kombhobho ojikelezayo0iiklasi 1 kunye ne-5 kuxinzelelo -2500Pa (-10 in.wg) .Kwaye ingatshintshwa njengesicelo somthengi.

1. I-bead ye-welding bead echanekileyo kufuneka ihambe kakuhle, ukufezekisa i-welding-side-side kunye ne-double-sided forming, ingaphakathi kufuneka liphuculwe ngokugudileyo, kungabikho pores, kunye nomgca wokugoqa we-folding surface kufuneka ube flat (malunga ne-90 °).

2. Inxalenye yombhobho womoya oza kupeyintwa (kubandakanya i-flange surface ngaphakathi kumbhobho) kufuneka ikhutshwe ngesanti, i-sandblasting roughness kufuneka ihlangabezane noburhabaxa be-3.0 G/S76, 40μm okanye ngaphezulu, kunye namasuntswana esanti ashiyekileyo kunye nothuli lwesinyithi ngaphandle. umbhobho kufuneka ususwe emva kwesanti.Qinisekisa ukuba umphezulu we-workpiece ye-duct ucocekile kwaye i-workpiece igqunywe ngefoyile ye-aluminium.

3. Idayamitha yombhobho ngaphezu kwe-2000mm iyafumaneka xa iceliwe.Ukutyeba kombhobho kwakhiwe kwi-SMACNA.Kwaye ingatshintshwa njengesicelo somthengi.