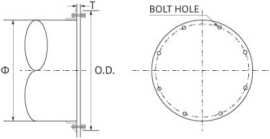

SUS304/ Teflon Coating End Cap

| Inombolo yenqaku. | Isazisi (mm) | OD (mm) | Uhlobo lokuQinisa | BC | Ukutyeba (mm) |

| EC-0100 | 103 | 153 |

| 133 | 3.0 |

| EC-0150 | 153 | 203 |

| 183 | 3.0 |

| EC-0200 | 203 | 257 |

| 233 | 3.0 |

| EC-0250 | 253 | 307 |

| 283 | 3.0 |

| EC-0300 | 303 | 367 |

| 340 | 3.0 |

| EC-0350 | 353 | 417 |

| 388 | 3.0 |

| EC-0400 | 403 | 467 |

| 438 | 3.0 |

| EC-0450 | 453 | 517 |

| 490 | 3.0 |

| EC-0500 | 503 | 583 |

| 544 | 3.0 |

| EC-0550 | 553 | 633 |

| 594 | 3.0 |

| EC-0600 | 603 | 683 |

| 644 | 3.0 |

| EC-0650 | 653 | 733 |

| 694 | 3.0 |

| EC-0700 | 703 | 783 |

| 744 | 3.0 |

| EC-0750 | 753 | 833 | NO | 794 | 3.0 |

| EC-0800 | 803 | 883 | or | 844 | 3.0 |

| EC-0850 | 853 | 933 | umnqamlezo | 894 | 3.0 |

| EC-0900 | 903 | 983 | Umnqamlezo weTie Bar | 944 | 3.0 |

| EC-0950 | 953 | 1033 | Umnqamlezo ophindwe kabini+iflange | 994 | 3.0 |

| EC-1000 | 1003 | 1083 |

| 1044 | 3.0 |

| EC-1100 | 1103 | 1183 |

| 1144 | 3.0 |

| EC-1200 | 1203 | 1283 | I-AXT ivuliwe | 1244 | 3.0 |

|

|

|

| 2 XC ross Tie Bar |

|

|

| EC-1300 | 1303 | 1383 |

| 1344 | 3.0 |

| EC-1400 | 1403 | 1483 | or | 1444 | 3.0 |

| EC-1500 | 1503 | 1583 | Umnqamlezo ophindwe kabini+iflange | 1544 | 3.0 |

| EC-1600 | 1604 | 1704 | Trellis | 1644 | 3.0 |

| EC-1700 | 1704 | 1804 | I-2X2 ye-Cross Tie Bar | 1744 | 3.0 |

| EC-1800 | 1804 | 1904 |

| 1844 | 3.0 |

| EC-1900 | 1904 | 2004 |

| 1944 | 3.0 |

| EC-2000 | 2005 | 2105 |

| 2044 | 3.0 |

Phawula:

Idayamitha yombhobho ngaphezu kwe-2000mm iyafumaneka xa iceliwe.

Ubukhulu bombhobho wakhiwe kwi-SMACNA "imigangatho yokwakhiwa kombhobho ojikelezayo ** iiklasi ze-1 kunye ne-5 kuxinzelelo -2500Pa (-10 in.wg) .Kwaye ingatshintshwa njengesicelo somthengi.

1. Inxalenye yombhobho womoya oza kupeyintwa (kubandakanya i-flange surface ngaphakathi kumbhobho) kufuneka ikhutshwe ngesanti, i-sandblasting roughness kufuneka ihlangabezane noburhabaxa be-3.0 G/S76, 40μm okanye ngaphezulu, kunye namasuntswana esanti ashiyekileyo kunye nothuli lwesinyithi ngaphandle. umbhobho kufuneka ususwe emva kwesanti.Qinisekisa ukuba umphezulu we-workpiece ye-duct ucocekile kwaye i-workpiece igqunywe ngefoyile ye-aluminium.

2. Tsala izixhobo zombhobho kwigumbi lokugquma, qalisa ukupeyinta, ukutshiza ngomatshini wokugquma we-electrostatic powder kunye netyhubhu yompu yokutshiza eyongeziweyo, uhlengahlengise ixesha lokutshiza ngokumodareyitha ngokweempawu zemathiriyeli ekrwada yemizuzu eyi-15 ~ 20, kunye noluhlu lobushushu be-sintering. 285°~300°C.

3. Emva kokuba i-workpiece igqityiwe, umphandle wetyhubhu uncanyathiselwe ileyibhile yesatifikethi se-FM, inombolo ye-serial ye-QC kunye neleyibhile yenkcazo yemveliso.Umlomo weflange uvalwe ngepleyiti ye-PE okanye ibhodi ye-PP engenanto, kwaye ilungiswe nge-tape yeplastiki yombhobho.

Idayamitha ye-4.Duct ngaphezulu kwe-2000mm iyafumaneka ngesicelo.Ukutyeba kombhobho kwakhiwe kwi-SMACNA.Kwaye ingatshintshwa njengesicelo somthengi.